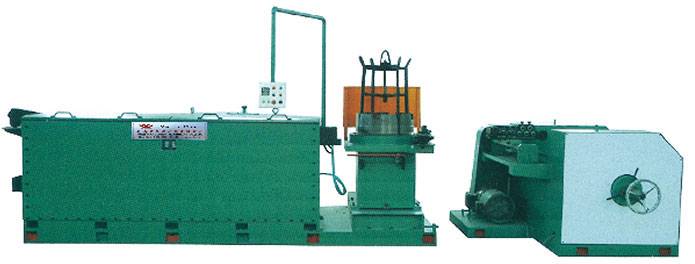

Heavy wet wire drawing machine+Spool take-up machine

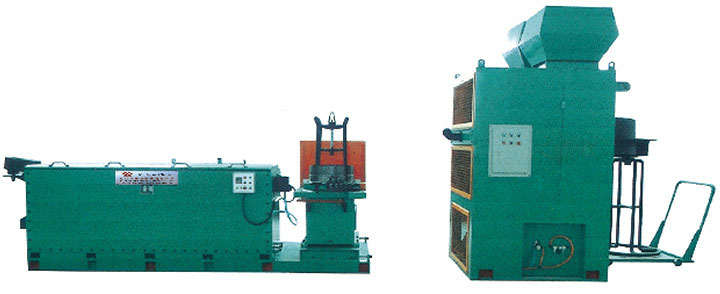

Heavy wet wire drawing machine+Coiler

Main Technical Parameters

| Items |

Unit |

LT8/

560-

650 |

LT11/

560-

650 |

LT13/

560-

650 |

LT15/

500-

560 |

LT17/

500-

560 |

LT11/

450 |

LT13/

450 |

LT15/

450 |

| Diameter of capstan |

mm |

560/650 |

560/650 |

560/650 |

500/650 |

500/650 |

450 |

450 |

450 |

| Drawing dies |

time |

8 |

11 |

13 |

15 |

17 |

11 |

13 |

15 |

| Max wire diameter |

mm |

Φ8~6.5 |

Φ8~6.5 |

Φ8~6.5 |

Φ6.5 |

Φ6.5 |

Φ4.5 |

Φ4.5 |

Φ4.5 |

| Min outlet diameter |

mm |

Φ4~3.0 |

Φ3.0~2.2 |

Φ2.5~2.0 |

Φ1.6 |

Φ1.4 |

Φ1.8 |

Φ1.4 |

Φ1.2 |

| Drawing speed |

m/min |

200 |

250 |

250 |

280 |

280 |

260 |

280 |

280 |

| Into the line intensity |

Mpa |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

| The total compression ratio |

% |

75~

78.70 |

85.94~

88.54 |

90.23~

90.53 |

93.94 |

95.36 |

84 |

90.32 |

92.89 |

| Average compression ratio |

% |

15.91~

17.58 |

16.33~

17.88 |

16.38~

16.58 |

17.05 |

16.52 |

15.35 |

16.44 |

16.16 |

| Motor power |

Kw |

155~130 |

130 |

130 |

130 |

130~

90 |

75 |

75 |

75 |

| Dimensions |

mm |

5800×3500×1840 |

5780×3300×1640 |

| Weight |

t |

11 |

11 |

11 |

11 |

11 |

9.5 |

9.5 |

9.5 |

Reducer of the machine applies 8-moudule herringbone gear and the gear of inlet is 10-moudle with speed ratio of 1:1. Material for axis of high-speed gear is high-frequency quenching 40Cr. Tower wheel can be made from common cast steel 55#, common cast steel 55# with high-frequency quenching, and common cast steel #55 painted by tungsten carbide according to customers' demand. Transmission bearings are all famous products. Charging system applied sectional coupling that obtain proper bearing of the axis. Reducer, wet box and charging box are on the same base easy installation and lifting. The surface painting is of high grade and both internal and external of electric-control cabint applies plastic-apraying process. It is divided into common control and variable-frequency control. Electric parts are all Chinese or international famous brands.

Main Technical Parameters

| Items |

Unit |

LTA11/350 |

LTA13/350 |

LTA15/350 |

LT15/350 |

LT17/350 |

LT15/200 |

| Diameter of capstan |

mm |

350 |

350 |

350 |

350 |

250 |

250 |

| Drawing dies |

time |

11 |

13 |

15 |

15 |

17 |

15 |

| Max wire diameter |

mm |

Φ3.5 |

Φ3.5 |

Φ3.5 |

Φ2.2~2.8 |

Φ1.2~1.7 |

Φ1.0~1.2 |

| Min outlet diameter |

mm |

Φ1.5 |

Φ1.3 |

Φ1.1 |

Φ0.6~0.8 |

Φ0.4~0.6 |

Φ0.28~0.36 |

| Drawing speed |

m/min |

330 |

330 |

330 |

420 |

420 |

315 |

| Into the line intensity |

Mpa |

≤1100 |

≤1100 |

≤1100 |

≤1100 |

≤1100 |

≤1100 |

| The total compression ratio |

% |

81.63 |

86.20 |

90.12 |

92 |

88 |

82 |

| Average compression ratio |

% |

14.28 |

14.13 |

14.30 |

15.5 |

12.0 |

11.0 |

| Motor power |

Kw |

55 |

55 |

55 |

37~45 |

18.5~22 |

7.5~11 |

| Dimensions |

mm |

5480x 3300x1640 |

2600x1300x1350 |

1700x1240x1280 |

| Weight |

t |

4 |

4 |

4 |

3 |

2.8 |

1.5 |

|