|

|

|

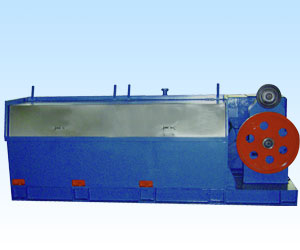

This company produces LT9-450 continuous annealing line used with pull-plus double-disc received Continuous Annealing Line (or, as the nose unloading line) production model, the formation of the entire production line continuous operation, drawing machine from a copper rod into the line of direct pull Ф8.00mm Model copper wire.

Annealing mode DC-annealing, annealing the use of advanced low-voltage power supply high current power supply, the control system adopts microcomputer intelligent control, equipment operation more stable, the maximum speed of 8 m / sec.

Take-up the use of a double-disk income line, the automatic switch, every minute continuous operation, without downtime for disk to avoid the re-start when silk phenomenon, to reduce unnecessary downtime and time-consuming. Plate with loading and unloading more convenient, simple and easy to operate.Ф2.78mm diameter according to the production output of up to 1.2 tons / hour, 20 hours a day, according to the production, daily output of up to 25 tons, can greatly reduce raw materials inventory and improve cash flow ratio.The entire production line can be done only one person from the Ф8.00mmt copper rods into the line to drawing, annealing, to close lines, and processes of the whole process. Class size of just one person a day, only two workers to complete the 25 tons of copper wire annealing production, qualifying specifications Ф1.78-Ф3.30mm.Wan Shun was 1.2 tons with automatic dual-income line pull Continuous Annealing Production Line can take into account the quality of copper, but also small and medium enterprises to adapt to variety of wire and cable industry specification entire, less liquidity, supply up with the status quo, thereby greatly reducing the copper prices fluctuated risks.

LT-1200 large Pull continuous annealing line supporting equipment as follows:

Actinomyces gantry frame wear die rolling machine 110KW motor control cabinet tip LT-9 mold copper big pull

LT-1200 annealing machine LT-1200 cabinet annealing operation of the main electrical cabinet automatic double-disc MD-up Machine XB-600 like the nose and unloading-ray machine (also purchased) can store 1 tonne of copper wire used in the production line when a large single-core BV capacity pay-off. |

|

|

|

|

|

LT9DieCopper Large Pull

Main technical parameters: |

|

Inlet wire diameter |

Ф8.0mm |

|

Outlet

diameter |

Ф1.78mm—Ф3.30mm |

|

Drawing

number |

9Die |

|

Power |

110KW |

|

Outlet velocityMAX |

480m/min |

|

Fixed speed wheel diameter |

Ф611mm |

|

Hourly output |

1200kg/h |

|

Drawing Wheel Material |

Cast tungsten carbide coating |

|

Dimension length 3000 * 1800mm Weight 6.5T width | |

|

|

| |

|

|

|

LT-15DieHigh-speed copper drawing machine

Main technical parameters: |

|

Inlet wire diameter |

Ф3.00mm |

|

Outlet diameter |

Ф0.5mm—Ф2.90mm |

|

Drawing number |

15模 |

|

Power |

30KW |

|

Maximum speed |

600m/min |

|

Fixed speed wheel diameter |

Ф350 mm |

|

Hourly output |

1000kg/h | | |

|

|

|

|

|

MDAutomatic Double Disc revenue Machine

The company's MD series full-automatic double disc closed-ray machine is mainly used for wire and cable industry revenue line, with PLC intelligent control, change set, the entire production line non-stop without deceleration, annealing non-silk, according to settings Cu wire length of the auto-changer and economic benefits are particularly notable.

Main technical parameters: |

|

Take-plate range |

PND400 PND500 PND 630(Custom) |

|

Slide the top tour |

220mm |

|

Take-up speed |

Torque Motor8m/s Inverter Motor 20m/s |

|

Power |

Torque Motor40NM*2 Inverter Motor5.5KW |

|

Equipment size |

Long2000*Weight1650mm | | |

|

|

|

|

LT-1200Annealing machine and electric control system

Main technical parameters:

Diameter range of annealing |

Ф1.78—Ф3.30mm |

|

|

480m/min Ф2.5Hours |

|

|

Low-voltage high-current short-circuit annealing |

|

Copper contact roller material |

Brass inlaid with pure cold-rolled nickel |

|

Annealing Wheel Material |

BeCu |

|

Wire Elongation at Break |

≥30% |

|

Cooling water temperature |

≤60℃ |

|

Cooling water temperature |

≤60℃ |

|

Dimensions |

Long1500*High2000Weight150(mm) |

|

Weight1.5T | | |